-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

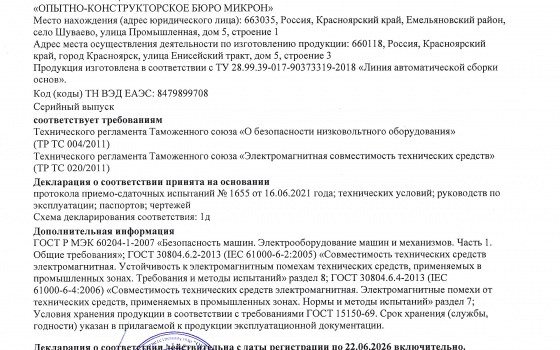

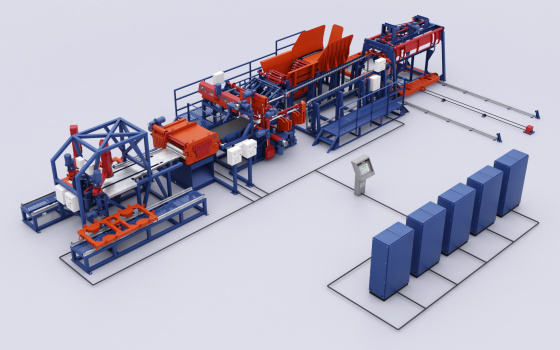

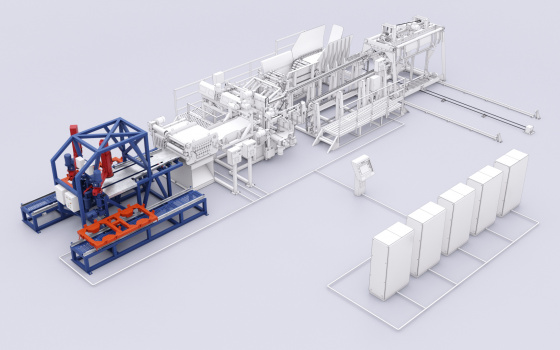

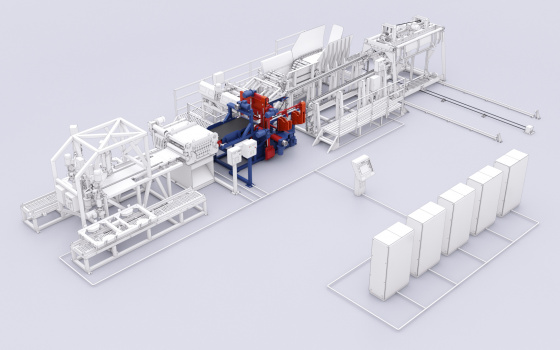

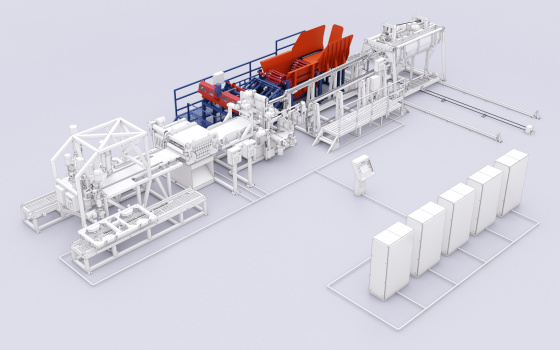

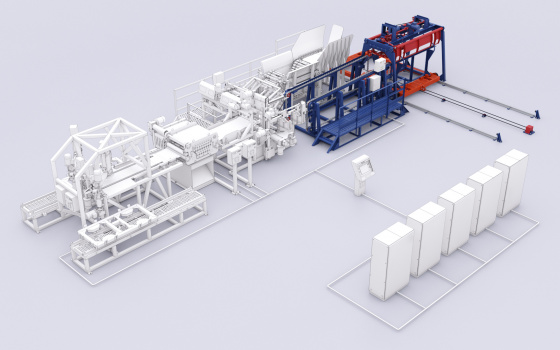

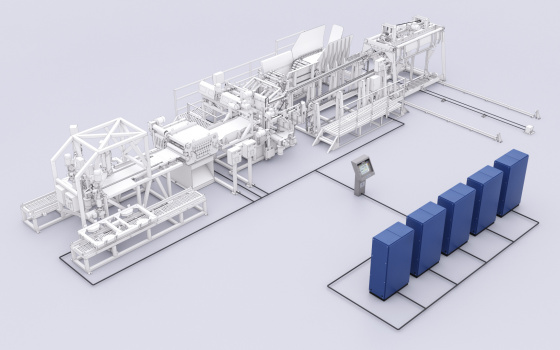

Automated base assembly line

The automated assembly line of bases includes:

- module for automated cleaving and assembly of cathode bases;

- module for optimal storage of cathode bases on containers;

- straightening and beading machine;

- module for optimal sorting and automatic feeding of rods to the assembly.

In March 2019 an automated assembly line of bases was put into operation at the Copper Plant of the Polar Branch of the “Nornickel” Company. The bases are used in the production of copper cathodes, which are the final products of the plant.

At the moment our company is engaged in manufacturing of the second line of AALB. The advantage of this line is its higher productivity. The AALB produces up to 12 copper bases per minute, the maximum hourly production can reach 720 copper bases. Each of them is a set of thin copper sheet about 3 kg and 1 mm thick, a lug and a rod. Another important advantage of the new line is the absence of a hydraulic system, which increases fire safety significantly, reduces the level of injuries and environmental pollution.

-

Category Automated lines