-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

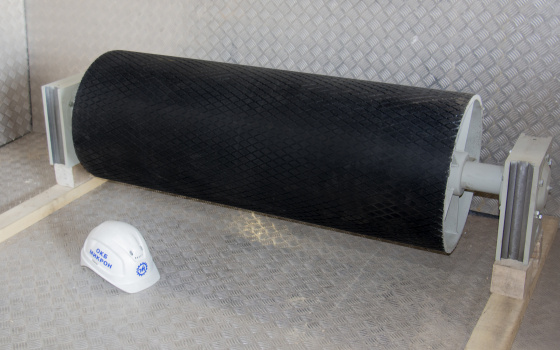

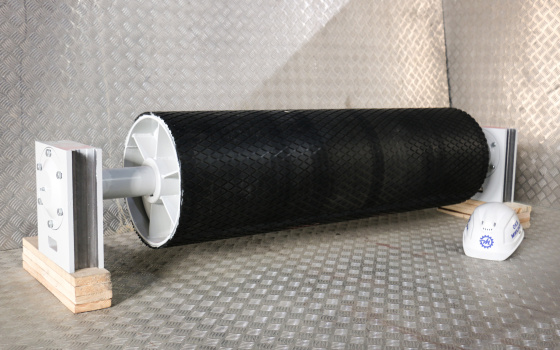

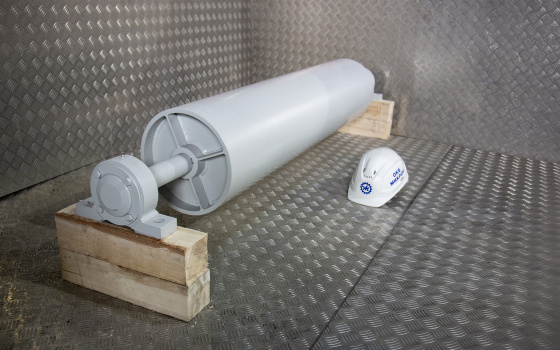

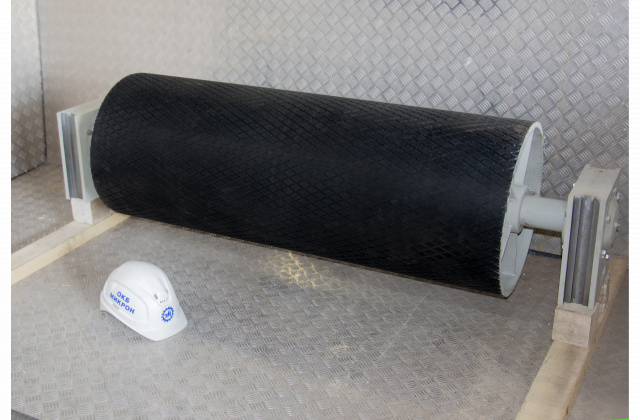

THE NON-DRIVEN CONVEYOR DRUMS

Non-driven reels are necessary for constant belt tension in a belt conveyor: to prevent sagging, regulation of movement, stretching during movement and avoiding slippage. The belt tension pulleys are installed in the middle of the conveyor on the belt reverse branch in the place of its bend or end, they are used on horizontal or inclined belt conveyors.

The design of belt conveyor drum consists of a cylinder shaped shell, a shaft, a steel casting disc and a clamping sleeve. Drums are covered with protective materials (liners), which increases the performance of the equipment due to its better adhesion to the conveyor belt, protects the surface of the drum from mechanical damage.

These products are made under the necessary belt widths and have different diameters. If necessary, they can be manufactured according to the customer's drawings and supplemented with other elements.

All components are manufactured by the company using modern machine tools, which guarantees their high quality and the ability to operate in different climatic conditions and environments.

-

Category Spare parts, tools and accessories