-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

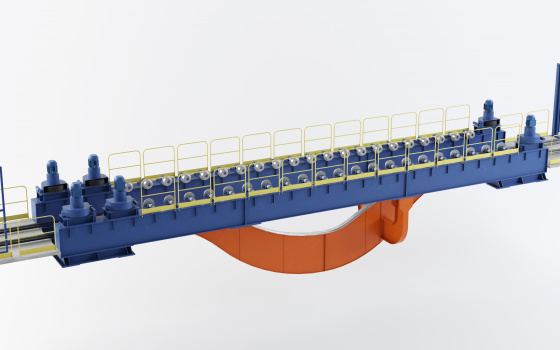

Bottom unloading complex of trolleys

This bottom unloading complex of trolleys (BUCT) into the receiving bin of lump ore of bunker-crushing complex.

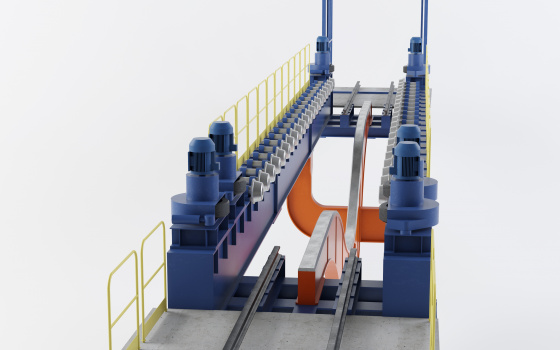

The complex is based on two rigid longitudinal beams. The system of roller protruding support blocks is installed on the beams. The rollers are mounted cantilevered and directed to the central axis of the complex. An unloading curve goes under. It is a box-shaped structure, which is protected by armor on the top. The broaching stations are equipped with a pressure rubber roller driven by a gear reducer and a pneumatic cylinder pressed against the cars.

When unloading, an electric locomotive drives up to the station. It is being clamped by power-drive stations and pulled along the entire complex. The broaching takes place behind the skis installed along the edges of the electric locomotive and trolleys.

The electric locomotive and the upper boxes of trolleys are rolled through the station at rollers, and the bottom fixed to the box opens downward cantilevered, providing quick and complete dumping of the transported ore. For correct operation the fifth wheel is installed on the openable part of the bottom which ensures smooth operation of the trolley during its unloading while driving through the station.

The advantages of this complex are unloading productiveness, ease of installation and maintenance.

-

Blueprint number Чертеж Download JPG 99.13 KB

-

Category Unloading stations

Specification

| Roller track length |

13,000 mm |

|---|---|

| Maximum load |

88 t |

| Wheelset track width |

750 mm; 900 mm |

| Station control |

automatic |

| Wheel clamping drive |

pneumatic |

| Weight |

40 tons |

| Overall dimensions: |

|

| Length over buffers |

16 700 mm |

| Width |

1300 mm |

| Height from rail head level |

3000 mm |