-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

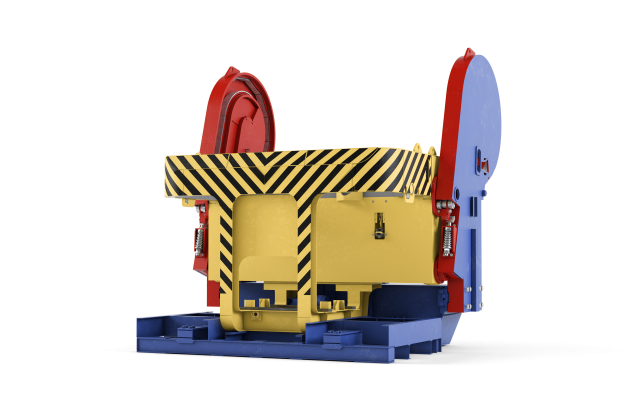

Trolley tipper

This trolley tipper is designed to provide open-side dump in mines by lifting and turning trolleys into the position that ensures complete unloading of the transported cargo at the tipper level.

The tipper is an electromechanic device which consists of fixed and movable metal structures.

The main elements of the tipper are a frame (fixed base) and a housing with the transmission line (movable frame).

This trolley is unloaded by lifting it along the tipper tracks and then its next tipping over (overturning).

Vibro-hammers installed on the movable frame are used to clean the remains of the unloaded cargo (materials). The trolley is placed and fixed in the tipper by means of centering units.

The centering units abut against the wheelset tires by means of cams, centering the trolley relative to the movable frame and fixing it from displacement. Also, mechanical stops and locks are used to fix the trolley.

-

Blueprint number Чертеж Download JPG 295.22 KB

-

Category Unloading stations

Specification

| Unit weight (without remote control) |

20 740 kg |

|---|---|

| Power supply voltage, 3 phases, 50Hz |

5.3 V |

| Number of simultaneously unloaded trolleys |

1 pc |

| Type of unloaded trolleys |

FT-5M (FT-4,5) - 750mm |

| Height at maximum lift of the trolley |

5 420 mm |

| Weight of the lifting part with a loaded trolley |

21 500 kg |

| Main drive power |

22 kW |

| Maximum density of the unloaded bulk material |

2,700 kg/m3 |

| Remote control |

|

| Turning time of the tipper platform |

1 min |

| Nominal rating power of the device is |

25.5 kW |

| Overall dimensions: |

|

| Length over buffers |

4 585 mm |

| Width |

4 255 mm |

| Height from rail head level |

4 624 mm |