-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

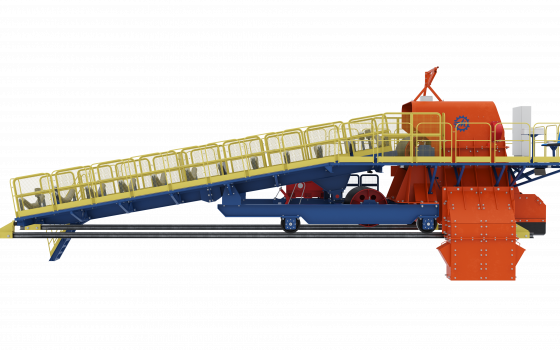

Dump trolley

This dump trolley is designed for unloading and regular distribution of ore (bulk, fine-grained or lump materials) coming from the belt conveyor. Unloading and distribution take place along the technological line from the conveyor to the bins on the one side of the conveyor.

This dump trolley is included in the equipment system of belt conveyors and is installed on the driving tracks above the receiving bins. By moving the trolley along the tracks, the incoming raw materials are dumped into the bin, when this happens it is possible not to dump aside, but to leave the raw materials on the feed conveyor belt.

The design of all components of the trolley ensures its stable operation and eliminates its overturn both during the move and during the operation of the belt conveyor.

The dump trolley consists of a conveyor, a dumping bin, a travel frame, a side dump box, service platforms, electrical equipment and a control system.

The trolley is equipped with two drives, one of them provides the trolley movement, the other one - lifting / lowering of the gate.

The conveyor is a welded, prefabricated steel structure. It is designed to support and send the belt with the ore being moved from the lower conveyor to the upper drum of the trolley.

The travel frame is a welded steel structure where the travel drive, the lower directional drum and wheelsets are mounted.

The bin is a welded steel structure lined with wear-resistant material up to 50 mm thick. In the bin there is a gate which ensures the dump of the incoming ore from the conveyor axis into the dump box.

-

Blueprint number Чертеж Download JPG 1.87 MB

-

Category Self-propelled transport

Specification

| Maximum power |

1,500 m3/h |

|---|---|

| Conveyor belt width |

1,600 mm |

| Conveyor belt thickness |

20 mm |

| Wheelset track width |

2,300 mm |

| Weight |

30 tons |

| Control system |

local manual |

| Overall dimensions: |

|

| Length |

14 180 mm |

| Width |

4 055 mm |

| Height |

4 555 mm |