-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

Big factory – big orders

«OKB MIKRON» have machined the largest part in the company's history

We are taking on bigger and bigger orders. This month the factory performed mechanical (milling and boring) machining of the middle section of the rotary platform of the walking excavator ESh-10/70. We worked with the inner surfaces of the center and swivel cups and rings. The finished part was sent to the customer at Borodinsky TMP (SUEK).

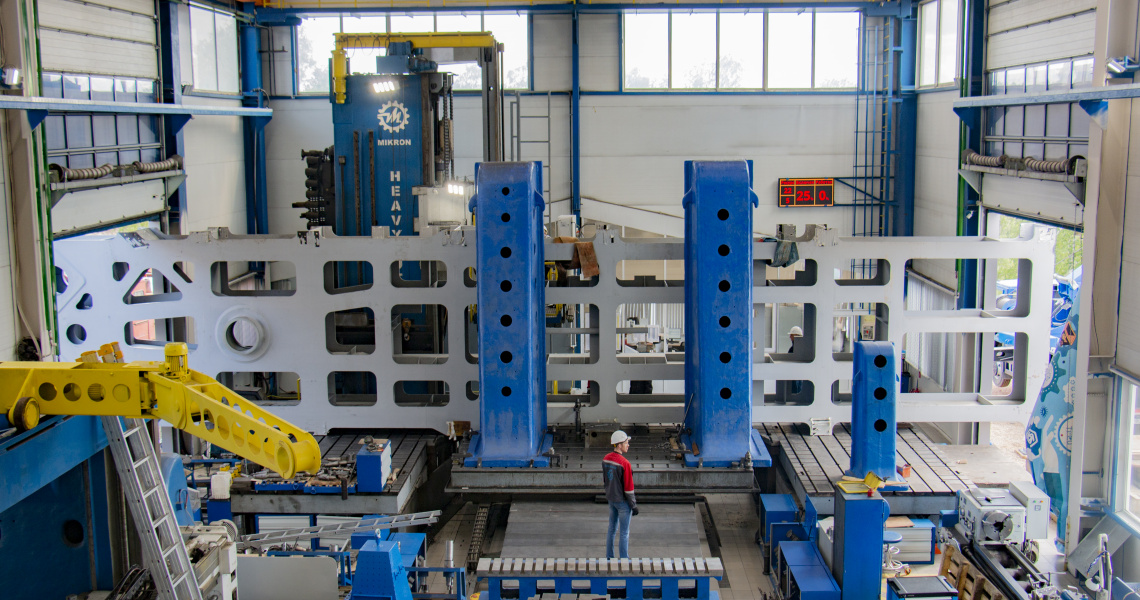

This is the first product of this type under the joint program of OKB MIKRON and SUEK. The part is the largest of those machined at our plant. Its length is 19 741 mm, width - 3790 mm, height - 1010 mm. On the photo you can appreciate the scale of the section weighing 31 200 kg.

In six days our engineers successfully coped with the order, taking into account the time to install the product on the machine table and its assembly after machining.

We undertook this task in full confidence that the capabilities of OKB MIKRON would allow to perform it without any difficulty. Unique technical solutions were used in the process. For example, in front of the working area of Heavycut machine in K-1 body we installed special gates, which allow machining of parts exceeding the size of the entrance area of the body.

In the nearest future it is planned to install an overhead crane weighing 64 tons in K-1, which will be put into operation next year. Such equipment will greatly simplify installation and removal of parts from the machine. So far this process is carried out with the help of three truck cranes.