-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

Fast, Accurate, On Time

The OKB MIKRON specialists have accomplished repair and restoration work on a bevel planetary reduction gear and an output splined shaft for the overhead passenger cable way at the Sheregesh ski resort.

It was a challenge because it was necessary to operate in a short time, using unique materials and engineering solutions. It was important to manufacture the shaft and restore the reduction gear before the first snow, since delivery to the station is carried out only on wheeled vehicles along the mountain slope. Breaking the deadlines would make lifting the reduction gear and the shaft impossible until the next spring.

The shaft was made of 40KhN2MA steel with a hardness of up to 300 Brinell units. Dimensions: length 3,900 mm, shaft diameter 240 mm, flange 480 mm, splined connection of 30 teeth with module 8, shaft weight 1,435 kg.

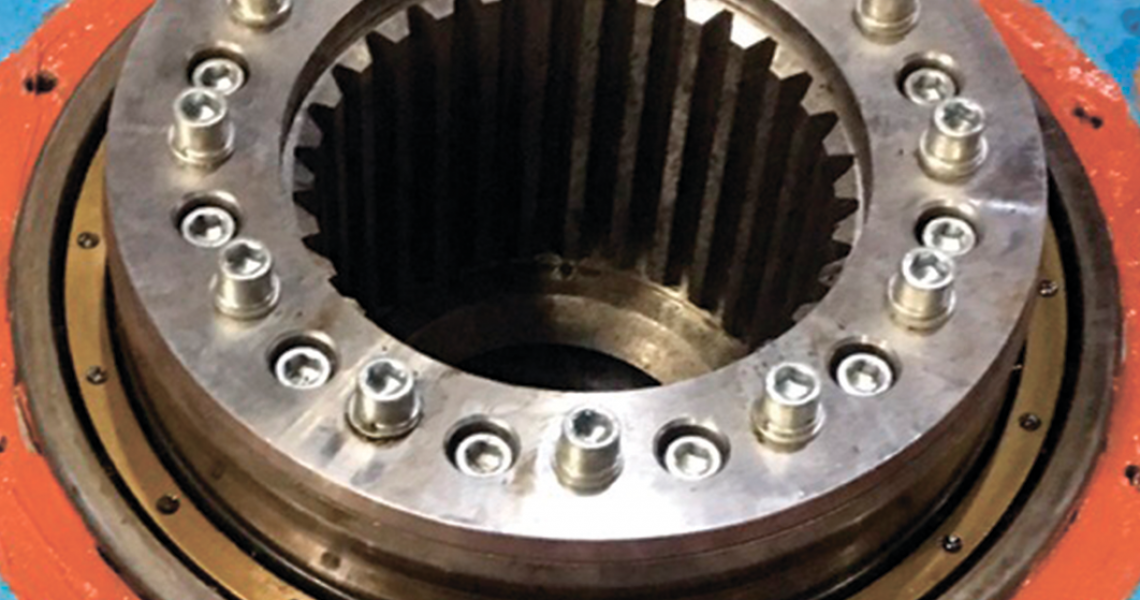

The unique character of the reduction gear repair lied in the manufacture of a transition splined bushing, which, using existing parts, made it possible to restore the reduction gear operability with minimum labor costs.

At the same time, all operating parameters were preserved: the total reduction gear weight of 4,550 kg, the 6.78 gear ratio, the output shaft moment of 2,400,000 Nm – exactly the moment transmitted by the manufactured shaft. Employees of our plant also carried out flaw detection and assembled the gear box.

On October 11, the assembled reduction gear and the shaft were shipped to the customer, and on October 18, the parts were lifted to the drive station and installed. In early November, a trial launch of the reduction gear in idle mode took place, thus confirming the quality of the work performed. On November 22, the cable way was launched with full load to be tested and prepared for commissioning.