-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

New Equipment Testing

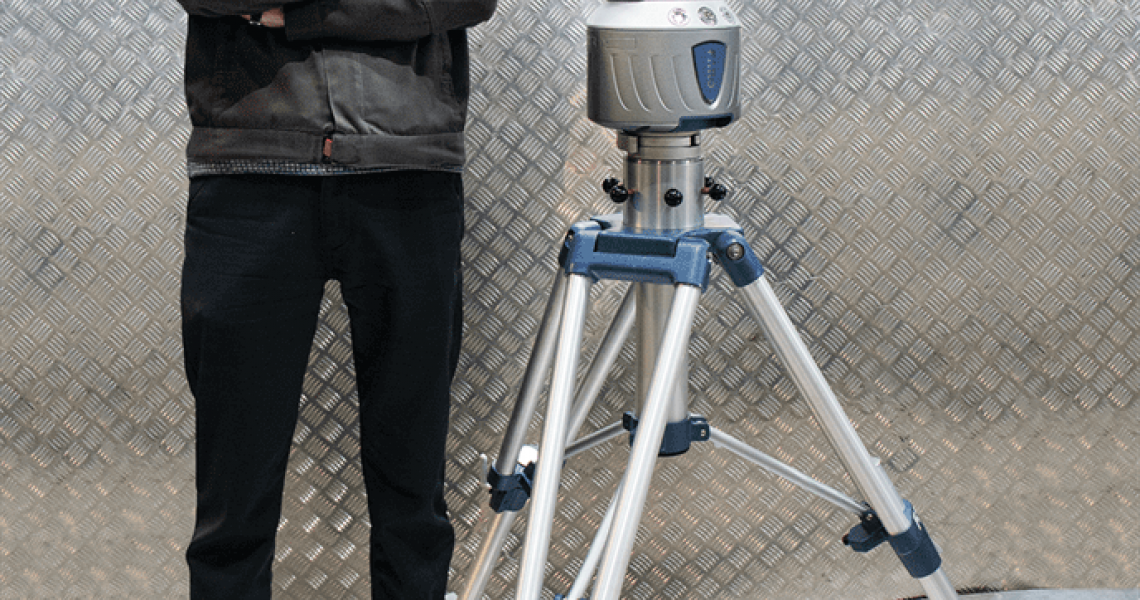

In December 2019, OKB MIKRON purchased the FARO Laser Tracker high-precision measuring equipment. This movable system allows making simple, fast and accurate measurements to optimize processes and solve the set tasks.

The FARO Laser Tracker is based on calculating the coordinates of the corner reflector centre by measuring two angles and radial distance using the absolute distance finder. Its speed is more than 1,000 measurements per second, range is from 0 to 80 m, nominal range of temperatures is from -15 °С to +50 °С, with the limit of permissible absolute error ±(16+0.8*L) μm.

It is noteworthy that with the integrated use of the equipment, its capabilities expand. Using the tracker together with the measuring arm allows capturing hidden points located behind corners or inside holes. With this solution, it has become possible to fulfill tasks such as monitoring, reverse engineering and comparing parts to CAD drawings.

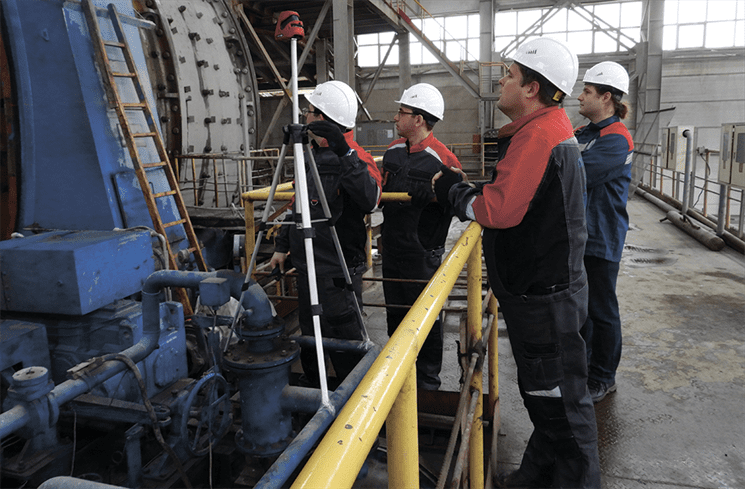

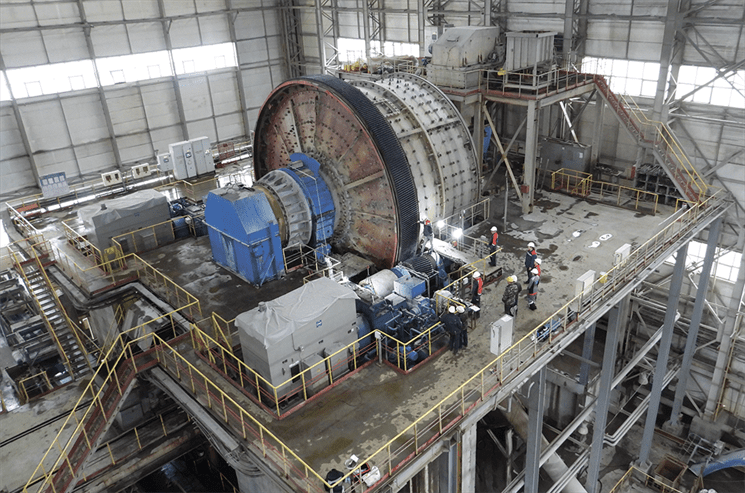

Thus, for example, this February the equipment proved excellent during a trip of the OKB MIKRON specialists to the Almalyk Mining and Metallurgical Complex, Uzbekistan. It was applied there to carry out a set of measurements at the manufacturing facility. Since 2016, the mill could not be brought to the rated capacity, as an increase in the workload resulted in the mill's self-destruction.

The FARO Laser Tracker is sensitive enough to vibrations, so we did not take the risk of going by plane

and decided to transport it on our own, by corporate car. The high cost of equipment made it necessary to obtain a customs declaration for temporary import and export, which took three weeks. Finally, our team hit

the road. Despite thorough preparation for the trip, there were still some troubles. For example, in Kazakhstan, the OKB MIKRON team faced snow drifts, ice and 700 kilometres of off-road conditions...

The management of the Almalyk MMC, interested in the positive result, assisted the Krasnoyarsk specialists. The OKB MIKRON team confirmed its professionalism by successfully completing all the necessary measurements.

At the moment, the calculations and analysis of the data received are ongoing. By the end of March, the technical proposal will be ready, and we are confident that it will help to determine the reason of incorrect equipment functioning and eliminate the problem.