-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

Manufacture of Parts for Thickeners by MIKRON

Thickeners are continuously operating units for thickening of any suspensions by dividing it into solid and liquid constituents.

Thickeners are used at mining and processing plants, in metallurgical, oil, coal and chemical industries, as well as other economic sectors.

KANEX Group has considerable experience in design and supply of traditional and high-speed thickeners and clarifiers as well as complexes for producing high-density pulps. In the group, the design bureau established in 2014 in Irkutsk is responsible for the design of processing equipment. The department provides companies of the mining and metallurgical sector with a full range of services from the development and reconstruction of small process units to the modernization of workshops and concentration facilities, as well as commissioning of new plants, which use all types of mineral raw materials and various processing technologies in their operation.

Professional skills of the team along with modern computer technologies allow developing the entire line of equipment (including

non-conventional), such as flotation machines, thickeners, sorting machines, setting tanks, slurry splitters, hydrocyclones and aeration units. Most of the projects are completed by our colleagues for the largest Russian and foreign companies, such as Eurochem, UGC, Polyus Zoloto, Norilsk Nickel, UMMC, Anzob, Kazzink, etc.

In 2020, a contract was signed for the supply of spare parts for several Norilsk Nickel MMC thickeners.

The KANEX Group is planning to manufacture thickeners in the framework of production cooperation. Capacitive equipment and oversized metal structures requiring no mechanical processing will be supplied by Kyshtym Machine Building Association, while oversized parts requiring mechanical processing will be manufactured at the OKB MIKRON industrial site.

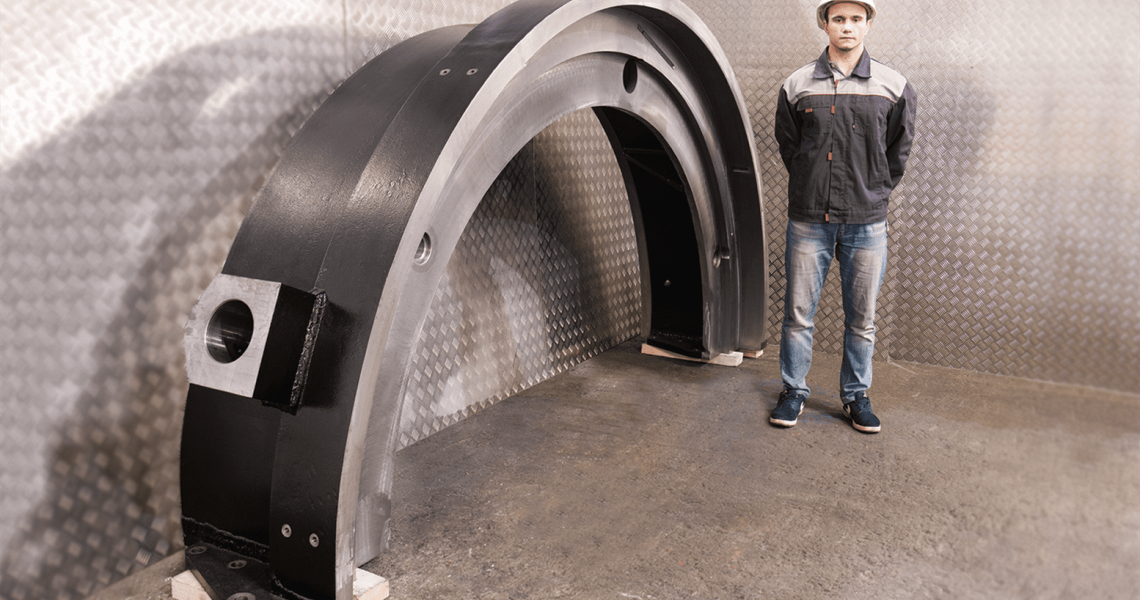

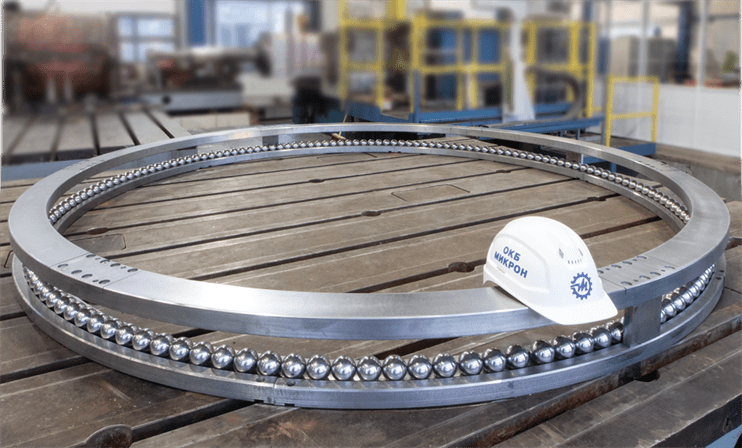

A thrust bearing and a movable support are the first parts already manufactured at our production facility.

In Russia, enterprises producing thrust bearings for thickeners use turning-and-boring lathes. Our offer is distinguished by development of a turn-milling technology.

A bearing is made entirely on the HEAVYCUT five-axis processing centre. The company managed to comply with all technical requirements and deliver the product of high quality.

At Russian enterprises, the movable support is usually cast. As for our company, a welding technology with subsequent mechanical processing was applied.