-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

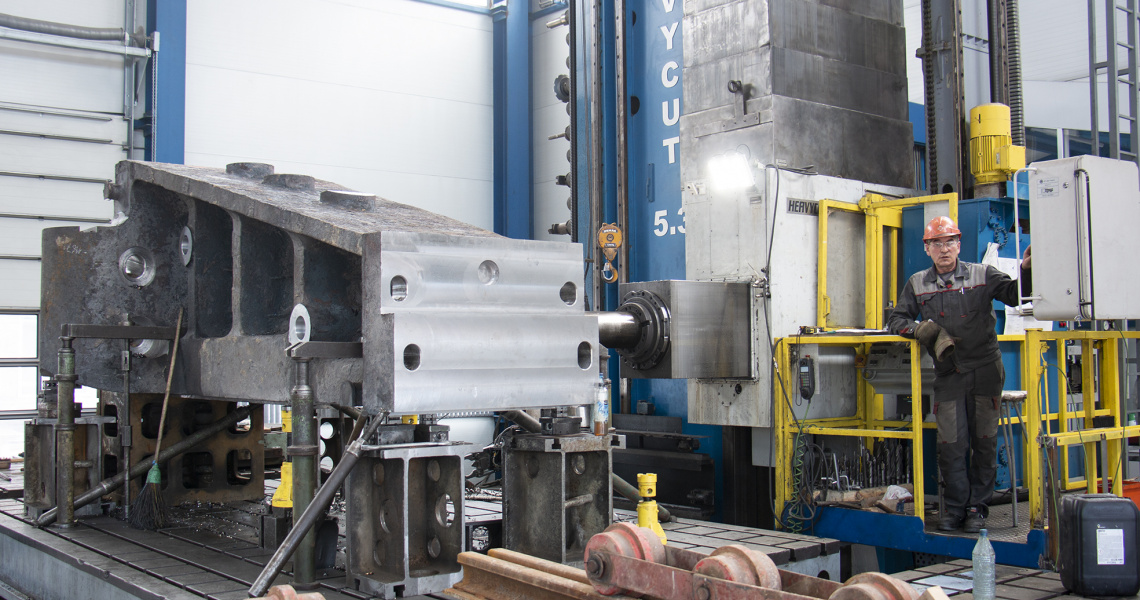

Hammer Frame

Hard work was required to fulfil the order itself. While manufacturing one frame, about 7 tonnes of chips were removed, over 50 quality surfaces were processed using more than 15 units of various metal cutting tools and tooling components, including those produced in-house. In addition, more than 10 programmes for automatic processing were written. Such close attention to tooling and processing modes was required, in particular, due to the parameters of the hammer frame. For example, the diameter of the deepest hole was 80x1350 mm.

The order was fulfilled for New Technologies – IC (Chelyabinsk) and Urals Stampings Plant (Mechel) (Chebarkul).