-

"Deep Bypass Krasnoyarsk" highway at 18 km, building 1

_1.jpg)

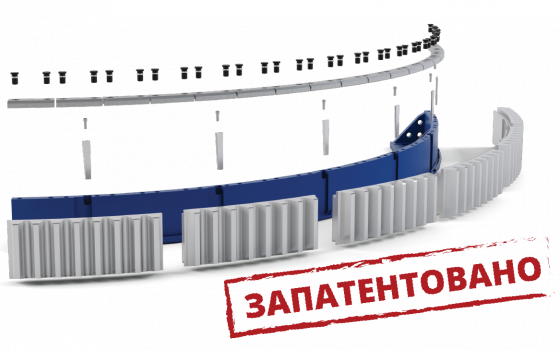

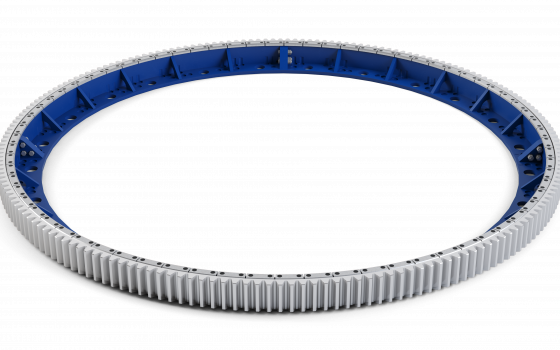

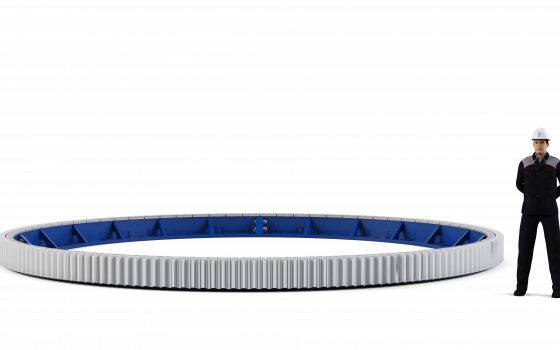

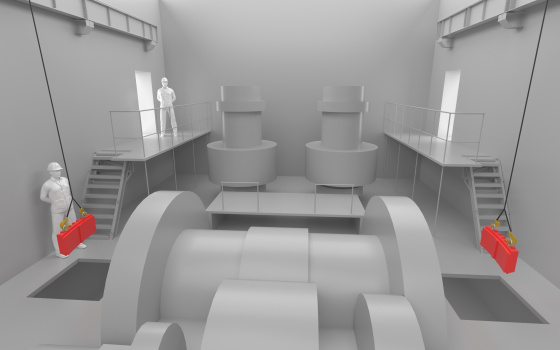

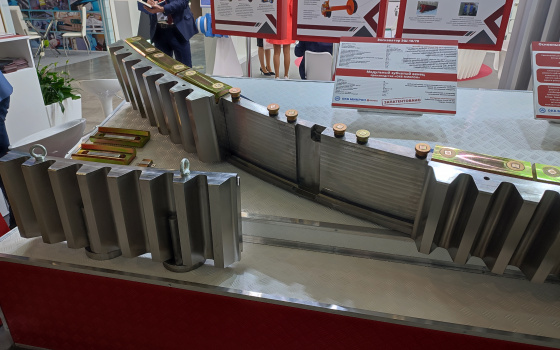

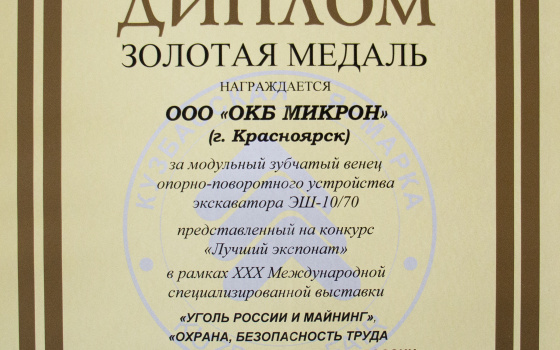

GEAR RIM OF A EXCAVATOR’S ROTARY SUPPORT ESH-10/70

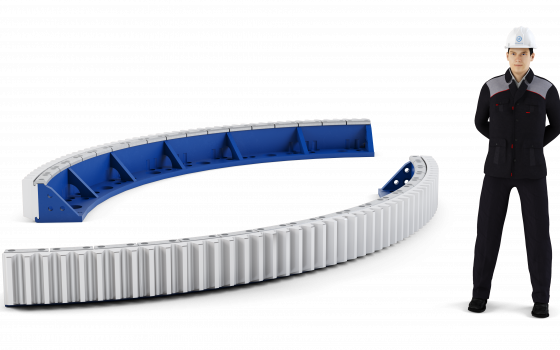

The toothed ring gear of the excavator ESh-10/70 is one of the main power units of the swing mechanism. Method of attachment to the support base is mechanical.

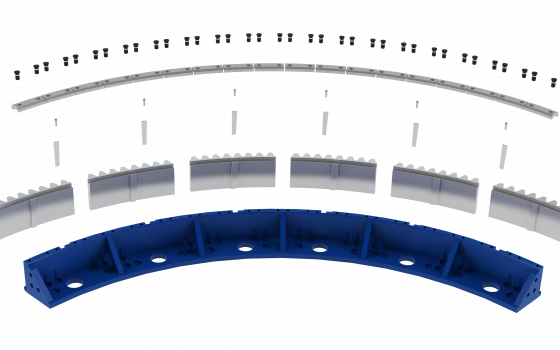

The Material: Gear modules are made of steel 40 ХН, casing is made of steel 35.

Advantages of the toothed ring:

Increase of service life by 30-50% in relation to the original cast design of the tooth gear, is achieved by using a forged billet as a material. Volumetric hardening of gear modules provides high hardness of tooth material, it is technically impossible to obtain the same indicators on a cast product.

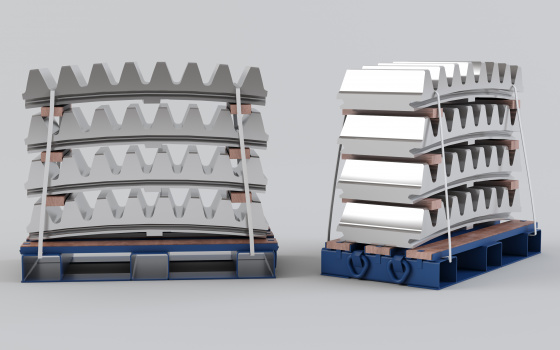

Reducing the cost of each subsequent gear repair due to the lower cost of a set of modules compared with the cost of a cast gear. Total weight of 24 modules in one repair set is 5,316 kg.

Decrease in cost for each subsequent repair of a ring gear by eliminating the need to dismantle a support base and reboring a ring gear.

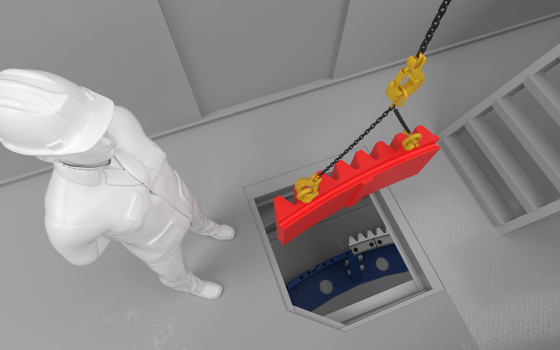

Modules replacement is made with the help of locksmith's tool using standard excavator lifting equipment.

Weight of one module is 221 kg.

-

Category GEAR RIMS

Specification

| The Module |

m=36 |

|---|---|

| Number of teeth |

z=192 |

| Profile angle |

20˚ |

| Offset coefficient |

-0,1 |

| Accuracy degree of GOST 1643-81 |

8-В |

| Constant tooth chord |

47,62-1,4-1,85 |

| Height to the constant chord |

16,418 m |

| Diameter pitch |

6912 m |

| Weight |

11741 kg |

| Number of sectors |

4 |

| Number of interchangeable modules |

24 |